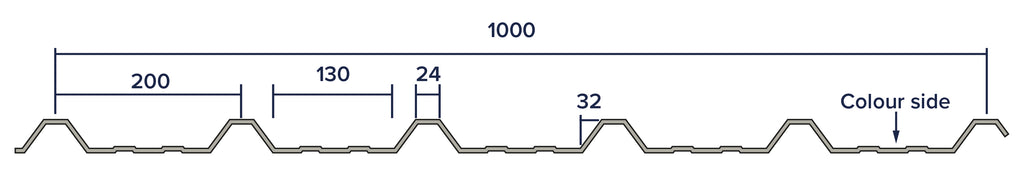

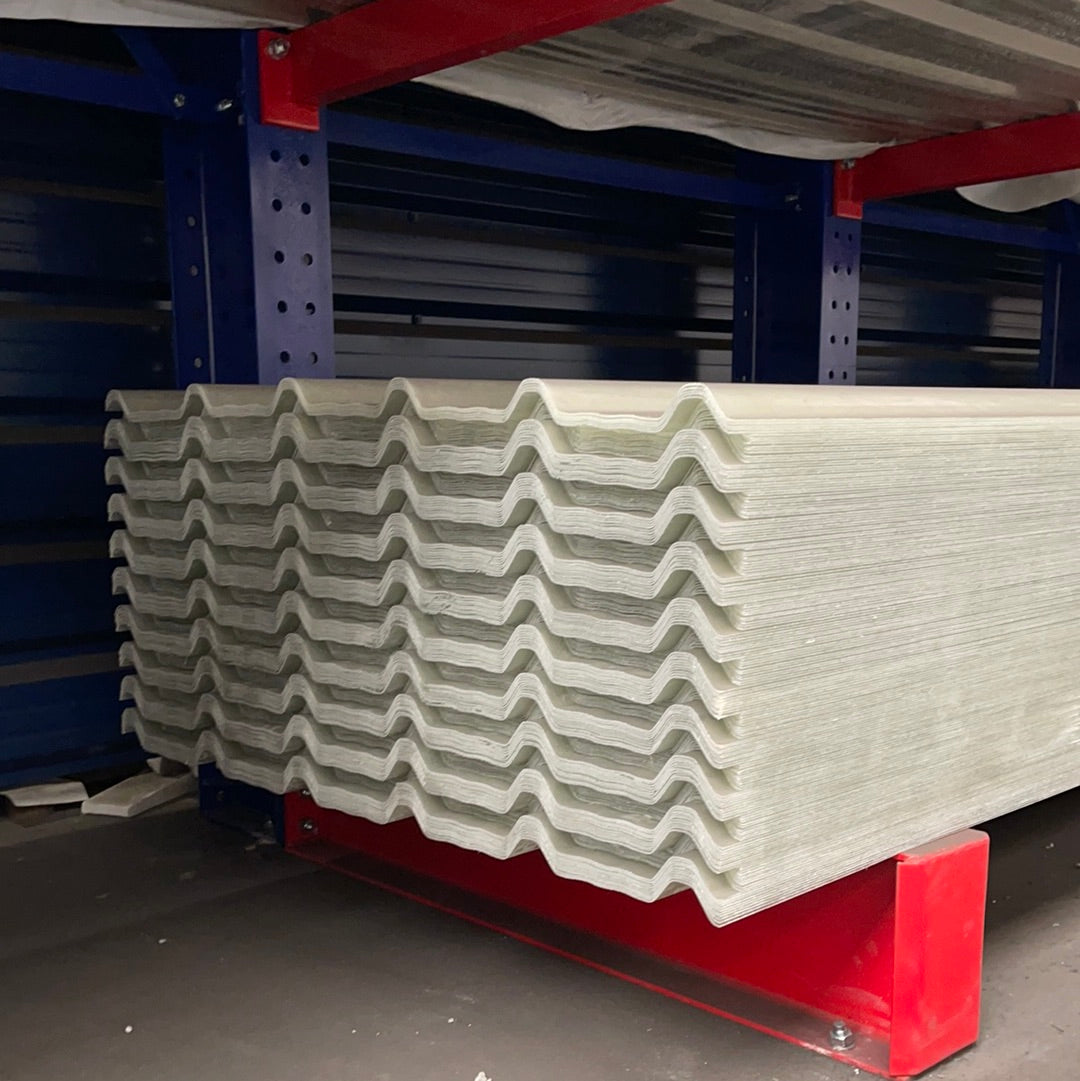

32/1000 Translucent GRP Rooflight Sheet

32/1000 Translucent GRP Rooflight Sheet

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

All deliveries are handled by our in-house transport team. We have a fleet of over 15+ different vans, rigids and articulated lorries!

Our deliveries are curb-side. Standard nationwide delivery is available on all orders in Great Britain and Scotland, but if you want your order faster, then we have different options available on the checkout.

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Product

Overview

All our GRP rooflight systems are CE marked to the strictest of safety standards.

ADVANTAGES

DURABLE

RUV stabilised weather resistant film, with a 20 year guarantee.

RANGE OF PROFILES

Huge stock available in most fibre cement and metal sheet profiles. All of our GRP Rooflights are in stock and available for Nationwide Delivery.

LATEST TECHNOLOGY

Manufactured with Anti-UV resins and to a minimum of 2.44kg/sq.m (SAB Class 3). Diffused light evenly spread and minimises shadows.

LATEST TECHNOLOGY

Manufactured with Anti-UV resins and to a minimum of 2.44kg/sq.m (SAB Class 3). Diffused light evenly spread and minimises shadows.

USES

- Industrial buildings

- Livestock buildings

- Equestrian buildings

Product

Dimensions